Written on: February 6, 2015 by W. Stephen Tait

Hello, everyone. Last month I discussed several corrosion and statistical technical terms that are relevant to spray package corrosion. This month I’ll expand that discussion by focusing on the relationship between commercial life and service life. These two lives can be used to determine if corrosion is too severe to market a formula-package system or slow enough that failures will not be observed by consumers before the product is exhausted from the package and it is recycled.

My original intention for this article was to discuss the relationship between commercial life and service life. While writing, I realized I also need to provide a more detailed discussion about what factors affect the magnitude of both commercial and service lives. Consequently, the discussion this month will cover the relationship between the two lives and the next one or two issuess will provide more detailed discussions on the factors that determine them. Let’s review the definitions of each.

Service life

Service life is the time when the package performs as specified. In other words, the package sprays and does not leak. Service life is determined by the type of package materials, package metal surface treatment (e.g., coated or uncoated), the physical form of your formula (e.g., emulsion or single phase) and the chemical composition of your formula. Service life is estimated from corrosion data from either a long-term storage test or electrochemical corrosion testing.

Commercial life

Commercial life is the time after filling that it takes for consumers to completely use the product and recycle the package. Commercial life is a function of the economy.

Figure 1 graphically illustrates a generic commercial life profile for containers filled during a given manufacturing batch (lot). Figure 1 has two curves because an actual commercial profile is affected by the economy. A growing economy normally decreases commercial life (short filling-to-recycle times) and a stagnant or declining economy normally increases commercial life (long filling-to-recycle times).

Figure 1 graphically illustrates a generic commercial life profile for containers filled during a given manufacturing batch (lot). Figure 1 has two curves because an actual commercial profile is affected by the economy. A growing economy normally decreases commercial life (short filling-to-recycle times) and a stagnant or declining economy normally increases commercial life (long filling-to-recycle times).

The Y-axis is the fraction of the containers from the batch that are empty (completely consumed) and recycled after a given time. The X-axis is the time after batch filling is completed. The time axis would be in days and is left blank to keep the curves generic.

The two vertical dashed lines in Figure 1 illustrate that the filling-to-recycle time ranges between approximately 2.5 and 3.25 time-units; one for a hypothetical growing economy and the other for a hypothetical stagnant or declining economy, respectively.

Figure 1 also illustrates that commercial life could be defined in several ways. For example, commercial life could be defined as the time when 90% or 95% of the filled containers are exhausted and recycled instead of 100%. It has been our experience that each type of formula-package system has a different commercial life range.

Figure 2 illustrates a situation where the estimated service life is greater than the commercial life. The second commercial curve is omitted for simplicity.

Figure 2 illustrates a situation where the estimated service life is greater than the commercial life. The second commercial curve is omitted for simplicity.

In this example the corrosion is very slow and empty packages are in the recycle stream long before container failures are expected to begin (failure is leaking or non-spraying). Thus, package corrosion in this example does not present a problem, as long as the economy doesn’t cause the commercial life to become longer than the service life.

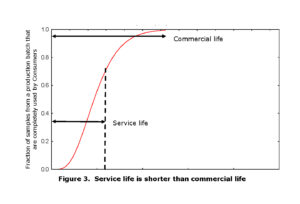

Figure 3 illustrates a situation where the commercial life is longer than the service life. This type of situation typically occurs when the corrosion rate is large. The vertical dashed line in Figure 3 shows that approximately 70% of the containers from a given manufacturing batch are exhausted and recycled after approximately 1.25 time units. In other words, approximately 30% of the filled containers at this time are still full and a fraction of the consumers would probably have packages that either leak or do not spray. The magnitude of the fraction could be low or high.

Figure 3 illustrates a situation where the commercial life is longer than the service life. This type of situation typically occurs when the corrosion rate is large. The vertical dashed line in Figure 3 shows that approximately 70% of the containers from a given manufacturing batch are exhausted and recycled after approximately 1.25 time units. In other words, approximately 30% of the filled containers at this time are still full and a fraction of the consumers would probably have packages that either leak or do not spray. The magnitude of the fraction could be low or high.

The corrosion illustrated in Figure 3 should be addressed before the product-package system is ready for introduction into the marketplace. The situation in Figure 3 also illustrates how a large difference between service life and commercial life is desirable to avoid unwanted,surprise failures caused by package variability, product chemical composition variability or economic fluctuations.

Next month, I’ll continue this discussion with more detail about the factors that determine the magnitudes of commercial life and service life.

We would be happy to teach our Elements of Spray Package (Aerosol Container) Corrosion short course at your R&D facility. Contact rustdr@pairodocspro.com or visit www.pairodocspro.com. Want a specific topic discussed in an issue of Corrosion Corner? Please send your suggestion/questions/comments to rustdr@pairodocspro.com. Back articles of Corrosion Corner are available from Spray. Thanks for your interest and I’ll see you in March.